The guide analyzes the four Rs of a circular carbon economy: Reduce, Reuse, Recycle, and Remove. It provides helpful information about how these principles support economic development and carbon cycle restoration.

What Is Circular Carbon Economy?

The circular carbon economy (CCE) takes a revolutionary approach to fighting climate change, using innovative carbon emissions management methods.

Traditional waste management views carbon dioxide (CO₂) as useless waste. However, the CCE sees it as a valuable resource that can be reduced through systematic processes, recycled, and removed or reused for the betterment of the environment.

Why Does It Matter?

For centuries, human use of fossil fuels has disrupted natural carbon cycles, creating a CO₂-overloaded atmosphere that has accelerated global warming.

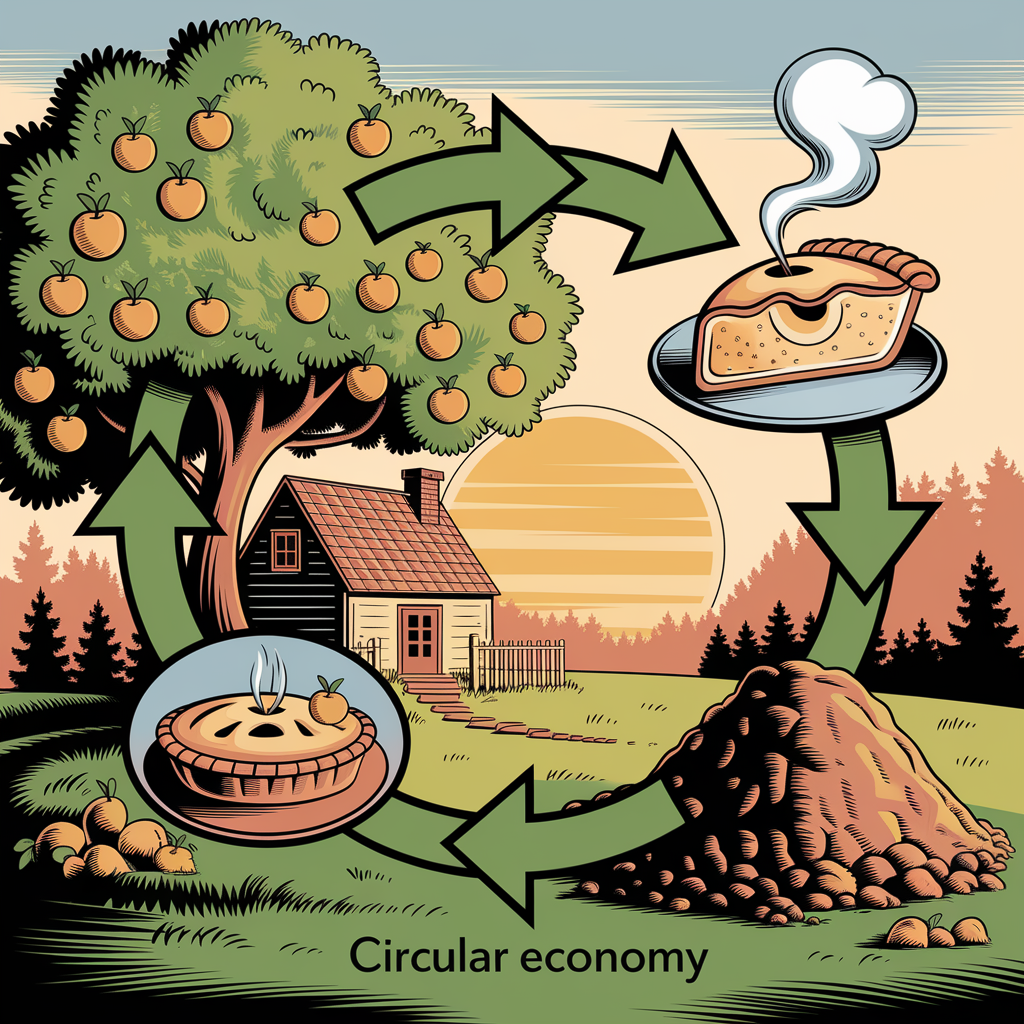

The circular carbon economy achieves its aim through operational systems that replicate natural circular processes. Human-made systems built by the CCE follow natural models to maintain continuous carbon cycles that reutilize waste to achieve maximum use of it: efficiency management instead of disposing of it.

This method mitigates climate change and unlocks new economic opportunities by converting waste emissions into marketable products such as fuels, building materials, and fertilizers.

The 4 Rs Of The Circular Carbon Economy

The circular carbon economy implements four core actions, known as the 4 Rs, to convert carbon emissions from climate hazards into usable resources.

Next, we’ll discuss how each “R” functions in plain terms, followed by a real-world example showing their combined impact.

1. Reduce: Cutting Emissions At The Root

The objective is to stop carbon from entering the atmosphere in the first place. This is done by shutting off the source, just like you manage water waste through a faucet at home. For carbon, this can be done by taking the following considerations into account:

- Cleaner energy can be used by switching from coal to solar or wind power.

- Manufacturers should invest in upgrading all factories and vehicles to minimize energy consumption.

- Preventing waste involves reducing methane leaks from oil wells or stopping the practice of flaring excess gas unnecessarily.

These examples represent how the reduction is the most direct way to shrink humanity’s carbon footprint.

2. Reuse: Giving Carbon A Second Life

CO₂ represents a valuable resource that can be captured to serve practical applications. For instance, using a discarded jar for another purpose represents a better choice than disposal. For carbon, this means considering the following alternatives:

- The production of synthetic jet fuel results from combining captured CO₂ with hydrogen.

- Concrete materials receive enhanced durability through CO₂ injection to improve their strength properties.

- The agricultural sector benefits from CO₂ emissions when greenhouses utilize the gas to enhance plant growth speed.

This carbon transformation into profitable products provides more financial reasons to capture carbon.

3. Recycle: Reinventing Carbon Through Chemistry

Recycling surpasses reuse because it transforms CO₂ molecules to create brand-new products. Like the process of turning plastic bottles into polyester fabric, that occurs through bottle melting. For carbon, this means:

- Chemical production turns carbon dioxide into methanol, which is an essential component of paint production and solvent manufacturing.

- The production of eco-friendly packaging depends on recycled carbon for manufacturing purposes.

- Conversion of carbon dioxide into urea enables farmers to obtain a widely used agricultural fertilizer.

Recycling depends on sophisticated technology which enables the production of an infinite number of carbon-based products.

4. Remove: Cleaning Up Leftover Emissions

COP29 made it clear that the world relies on methods to remove CO₂ from the atmosphere because certain emissions cannot be halted, like from airplanes. This is like using a sponge to absorb spilled water. Methods may include:

- Planting more trees—Forests absorb CO₂ through their photosynthetic process because they receive sunlight.

- Direct air capture—refers to machines that extract CO₂ from the atmosphere to store it underground.

- Biochar preparation—a process in which plant waste is oxygen-free and burned to develop charcoal, a carbon-capture agent for soil.

Removal balances carbon sources we currently cannot remove.

What Are The Benefits Of A Circular Carbon Economy

1. Climate Mitigation

Incorporating the 4Rs into operations would enable the CCE to reduce global industrial emissions by 50% by 2050. The circular economy saves millions of yearly car pollution emissions by using recycled CO₂ in cement making, and steel and aluminum recycling decreases mining’s carbon footprint.

2. Economic Opportunities

The CCE presents an opportunity to create trillions of dollars worth of economic value through carbon-based product and carbon removal service markets by 2030, like the initiative of the circular carbon economy Saudi Arabia—NEOM project. This project aims to demonstrate a sustainablethat uses circular carbon economy principles as its power source.

3. Resource Efficiency

A circular system reduces the need for new raw materials. Reusing plastics through reprocessing decreases the plastic waste reaching oceans by 50%, thus saving manufacturing energy.

Case Study Of CEMEX And Heidelberg Materials’ Oxyfuel-Powered Cement Plant

Step 1 – Oxyfuel Combustion Cuts Emissions

The plant implements oxyfuel technology because it substitutes cement kiln air with pure oxygen.

The process yields flue gas containing 70% or higher CO₂ concentration, which enables simpler capture operations when compared to conventional methods. Installing oxyfuel systems into existing kilns increases energy expenses by 40–50% but reduces clinker production emissions to about 90% during operation. (1) (2) (3)

The facility neutralizes higher electricity consumption by using renewable energy to power its air separation units (ASUs).

Step 2 – Embedding In Concrete

The carbon capture process involves injecting captured CO₂ into a carbonated water-cement suspension, which Northwestern University and CEMEX developed for concrete mixing. (4)

The concrete mixture allows CO₂ to form calcium carbonate crystals through chemical bonding, which eliminates the need for costly storage tanks and pipelines.

This modern carbonation method surpasses previous techniques by maintaining the material strength while reaching 45% sequestration efficiency. (5)

Step 3 – Closed-Loop Mineralization

During the carbonation process, calcium carbonate minerals form to replace cement industry limestone which serves as its main raw material.

The concrete manufacturing process forms an ongoing cycle where limestone calcination emissions are reused to make concrete binding agents.

The pilot initiatives conducted by Heidelberg Materials at their Colleferro Italian location demonstrate that carbonation techniques decrease the need for fresh limestone raw materials by 30%. (1)

Step 4 – Permanent In-Material Storage

The carbon dioxide from calcium carbonate seeps into concrete, where it remains bound until eternity. This method is superior to reforestation and direct air capture because it provides long-term carbon storage through low-maintenance concrete products.

The manufacturing process of one ton of concrete results in permanent storage of approximately half of CO₂. (4)

Result?

By integrating all 4Rs, the plant:

- The plant achieves cost reduction through energy conservation along with selling CO₂ emissions as a new revenue stream.

- The recycling of carbon materials helps decrease dependence on raw materials for production purposes.

- The establishment of green jobs, together with cleaner air, creates positive relationships within the community.

These comprehensive solutions resemble actual ventures, which demonstrate that circular systems function in real life at a large scale.

How You Can Support The Circular Carbon Economy

The circular carbon economy functions optimally when people and organizations make choices that support its guiding principles. To contribute practically, you can follow these tailored practices.

For Individuals

1. Reduce Energy Use In Daily Life

You should begin your carbon reduction journey with minor changes to your environmental impact. For instance,

- LED lightbulbs are a better option because they require less electricity and maintain their functionality for longer than normal bulbs.

- Devices consume power while connected to outlets, even if they remain plugged in an idle state.

- Use public transport systems or bicycles instead of driving your vehicle by yourself.

- The installation of a programmable thermostat at home provides optimal control of heating and cooling systems.

These steps produce energy savings together with reduced utility expenses throughout the long term.

2. Choose Products Designed For Circularity

When shopping, consider purchasing items from sustainable businesses that use recycled materials to make their products.

You should select products such as sneakers made from recycled ocean plastics, furniture made from reclaimed wood, and clothing brands that provide repair services. Choose your shopping items based on their small packaging and select containers that have returnable reuse capabilities (such as glass milk bottles).

The choices you make with your money lead businesses to adopt circular practices, thereby driving more circular practices into the market.

3. Advocate For Systemic Change

Significant progress emerges through combined people skills, although single actions also create meaningful change.

- Approach local government representatives to encourage the adoption of carbon pricing regulations, additions to renewable energy policies, and new recycling infrastructure.

- Community members should participate in groups that support urban gardening and tree-planting projects.

- Social media users should access educational materials to learn about the circular carbon economy.

Simple, friendly talks between people can also lead others to reconsider their daily routines.

For Businesses

1. Audit And Optimize Your Carbon Footprint

Your emissions analysis should start by identifying your organization’s main pollution sources.

Basic tracking systems help companies monitor their energy consumption at offices, factories, and supply chain locations. Regular equipment maintenance combined with switching to renewable energy providers are two examples of effective action.

Your company should partner with suppliers who adopt low-carbon operational methods, including electric-powered delivery services. When combined with other small alterations, reducing air travel for business meetings generates substantial emissions reductions.

2. Invest In Circular Innovations

Partner with startups or research institutions developing carbon capture technologies, bio-based materials, or waste-to-resource systems.

Leasing models should replace product sales because they drive manufacturers to construct durable items that can undergo refurbishment.

The support of green innovation enables businesses to discover new income sources alongside environmental sustainability improvements.

3. Design Products For Longevity And Reuse

Businesses need to redesign their product manufacturing process from the beginning. Manufacturers should develop modular products that permit simple maintenance or upgrade processes, such as smartphones with detachable batteries.

The replacement of mixed plastics with aluminum represents an ideal material choice because aluminum enables easy disassembly and recycling. The adoption of reusable containers alongside compostable packaging options should be used for product packaging.

Companies operate take-back programs that allow customers to send in used products for recycling. Products designed with circular thinking practices produce less resource waste while attracting more loyal customers.

Take Away – Making It Work Together

Aligning daily choices with the 4Rs, everyone—from households to multinational corporations—can help close the carbon loop and build a regenerative future.

The 4Rs function as interdependent steps that generate an endless cycle of carbon reutilization. This framework enables industrial organizations, including factories and farms, to address climate change by promoting innovation in their operations’ futures.

References

- Oxyfuel technology for carbon capture at HeidelbergCement plant Colleferro

- Oxyfuel : GCCA

- An overview of oxy-combustion | World Cement

- Process stores carbon dioxide in concrete without strength loss – Northwestern Now

- Revolutionizing Concrete: New Method Sequesters CO2 and Enhances Strength – Impact Lab